A pipe is a straight, pressure-tight, cylindrical hollow used in piping systems to transport various process materials.

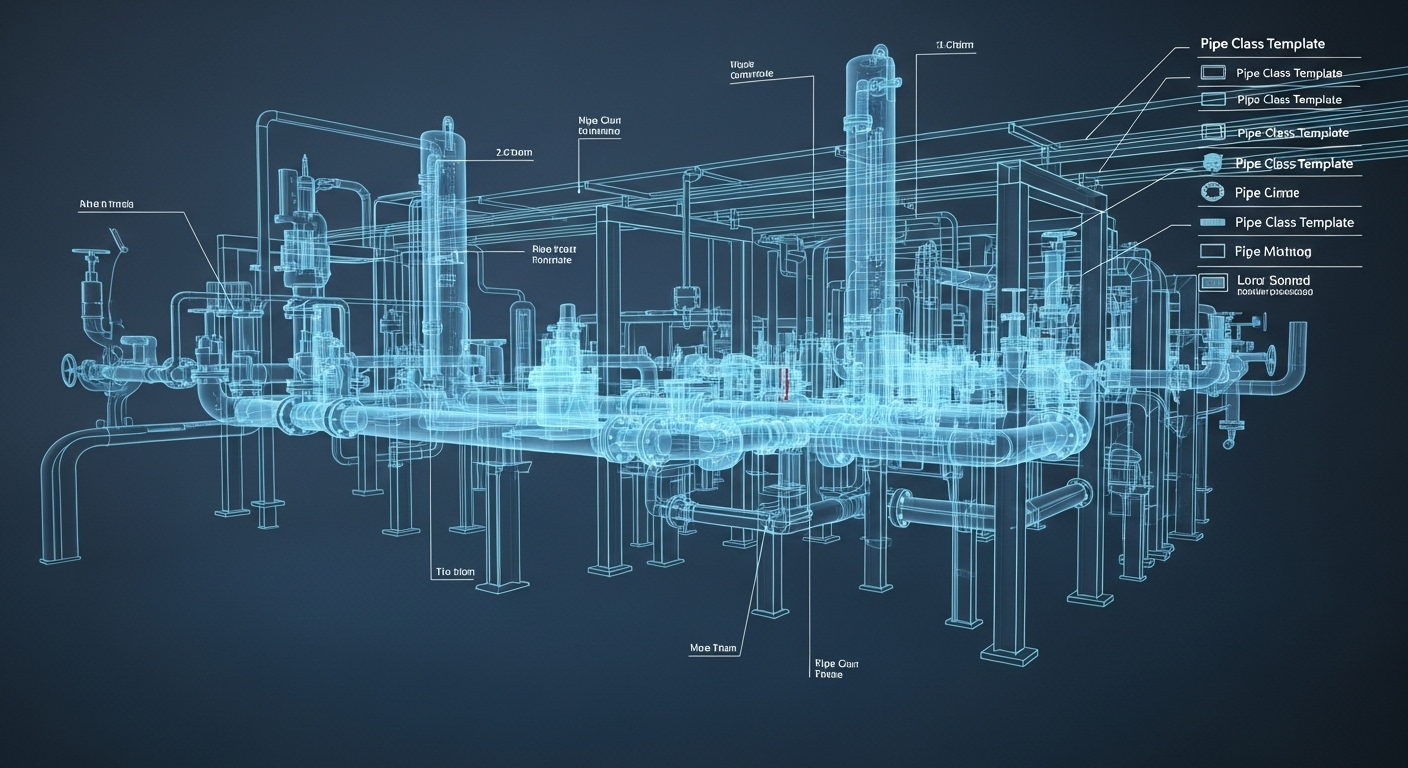

Ever looked at a sprawling industrial plant – perhaps an oil refinery, a chemical factory, or a power generation facility with pipelines connecting everything? These aren’t just random tubes; they’re the lifelines of industry, transporting everything from liquids and gases to even solids, moving raw materials, intermediate products, and final goods to their exact destinations.

But what exactly is a pipe, and what is a “pipe class”? Let’s break it down in a way that makes sense.

What is a Pipe?

At its core, a pipe is a straight, pressure-tight cylindrical hollow component used within a piping system to transport various process materials. Think of them as the veins and arteries of an industrial plant, ensuring that everything flows smoothly and safely.

Pipes aren’t a one-size-fits-all solution; they come in different types, primarily classified by how they’re made: seamless or welded.

- Seamless pipes are generally preferred for small and medium-sized applications.

- Welded pipes are often more economical for larger diameters and are further categorized by their welding method, such as Submerged Arc Welding (SAW), Electric Resistance Welding (ERW), Electric Fusion Welding (EFW), or High-Frequency Welding (HFW). For instance, American Piping Products stocks API 5L seamless and welded steel pipes, which are specifically designed for transporting petroleum and natural gas.

When choosing a pipe, engineers consider many factors beyond just what it carries. They look at material properties like:

- Ultimate Tensile Strength: How much tension it can withstand.

- Yield Strength: The point at which it starts to permanently deform.

- Elasticity: Its ability to return to its original shape after a load is removed.

- Hardness, Toughness, Creep Resistance, and Fatigue Resistance: All crucial for durability and longevity under stress.

Beyond these, practical elements like the cost of the material, its availability, and how easy it is to weld and manufacture also play a significant role in the selection process. Common pipe materials include various types of carbon steel, alloy steel, stainless steel, non-ferrous metals (like copper, nickel, aluminum), and non-metals (such as PVC, CPVC, HDPE). There are even composite pipes known as lined and clad pipes, which combine two different materials for enhanced reliability and cost-effectiveness.

You might also hear about “pipe schedules,” like Schedule 40 or Schedule 80. These numbers directly refer to the wall thickness of the pipe, with a higher schedule number indicating a thicker wall. This thickness is vital because it determines the pipe’s pressure rating and overall performance characteristics. Fun fact: for smaller pipes, the nominal size (e.g., 1-inch pipe) doesn’t actually match its outer diameter; it’s typically larger. However, for pipes 14 inches Nominal Pipe Size (NPS) and above, the outer diameter generally aligns with the nominal size.

What is a Pipe Class?

Now, let’s talk about pipe classes. Imagine trying to build a complex Lego set without instructions – you’d have a pile of pieces, but no clear idea how they fit together. A pipe class is essentially that instruction manual, but for industrial piping systems.

A pipe class is a categorization system that defines a specific set of compatible piping components and this is key, it’s not just pipes! It includes pipes, fittings, valves, flanges, gaskets, and other necessary accessories. The primary purpose of a pipe class is to standardize these components based on common design and construction criteria.

These criteria are deeply rooted in the specific operating conditions the piping system will face. This means considering the type of fluid being transported, the expected pressure and temperature ranges, and any potential for corrosion. For example, a pipe class for high-pressure steam would specify materials that can handle intense heat and pressure, along with appropriate corrosion allowances.

So, what kind of information would you find in a pipe class document?

- Material Specifications: What materials are allowed for pipes, fittings, flanges, and valves.

- Size Range: The acceptable diameters and wall thicknesses.

- End Connections: How components connect (e.g., threaded, welded, flanged).

- Component Types: A list of all standard parts like elbows, tees, reducers, and various types of valves (gate, globe, check, ball valves).

- Corrosion Allowance: An extra thickness added to pipe walls to account for material loss over time due to corrosion.

- Pressure-Temperature Ratings: The maximum pressure and temperature the components can safely handle.

- Branch Tables: Details on different branch connections, including their size, type, and location, to optimize fluid flow.

- Special Assemblies: Requirements for unique components like expansion joints or strainers.

- Support Notes: Guidelines for installation, maintenance, and how pipes should be supported and anchored.

- Compliance with Standards: References to industry codes like ASME, API, or ASTM that the components must adhere to.

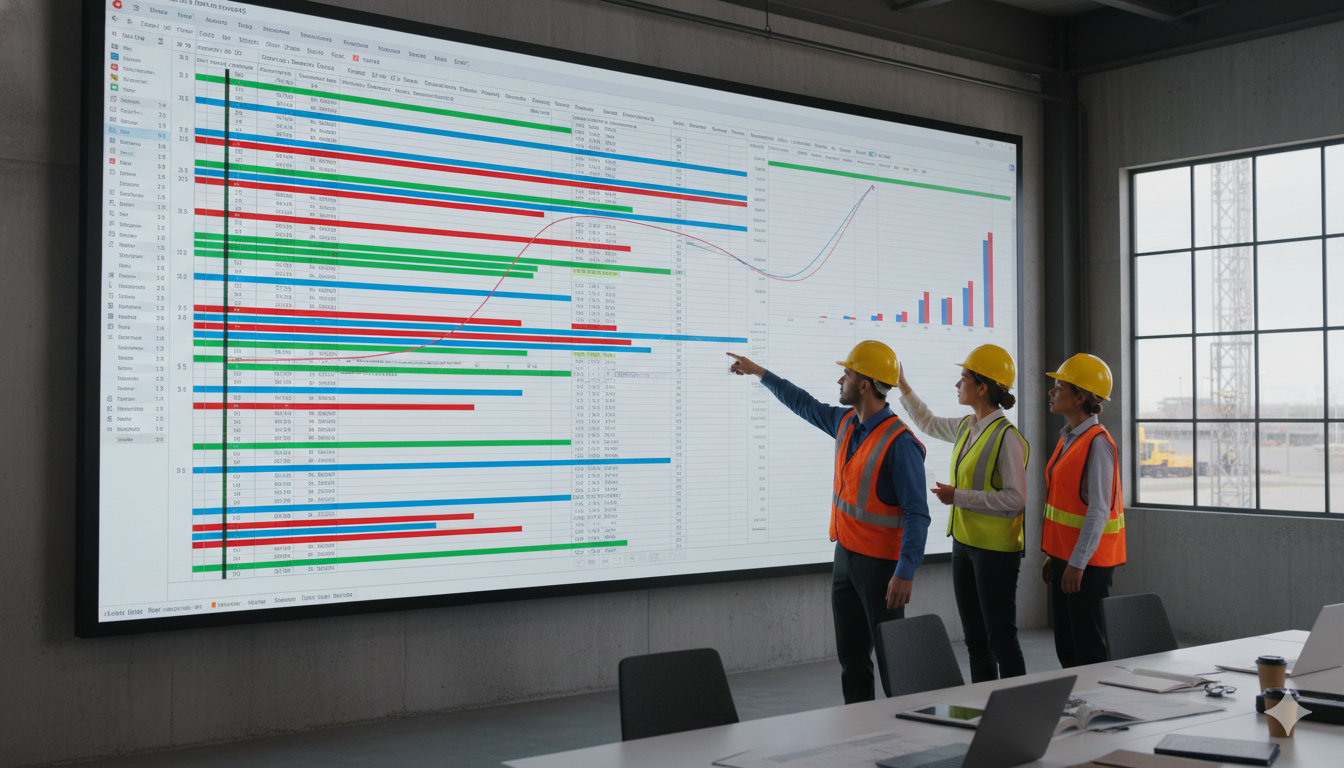

Pipe classes are created by multidisciplinary teams within organizations that own, operate, or design these systems, including piping engineers, process engineers, materials engineers, and quality assurance professionals. They ensure that every part of a piping system is compatible and works together safely and efficiently under its intended conditions.

In essence, while a pipe is the fundamental conduit, a pipe class provides the comprehensive framework to ensure that all components of a piping system work together seamlessly and safely. This structured approach is what allows industrial plants to operate with the reliability and efficiency we depend on every day.