Piping Specifications

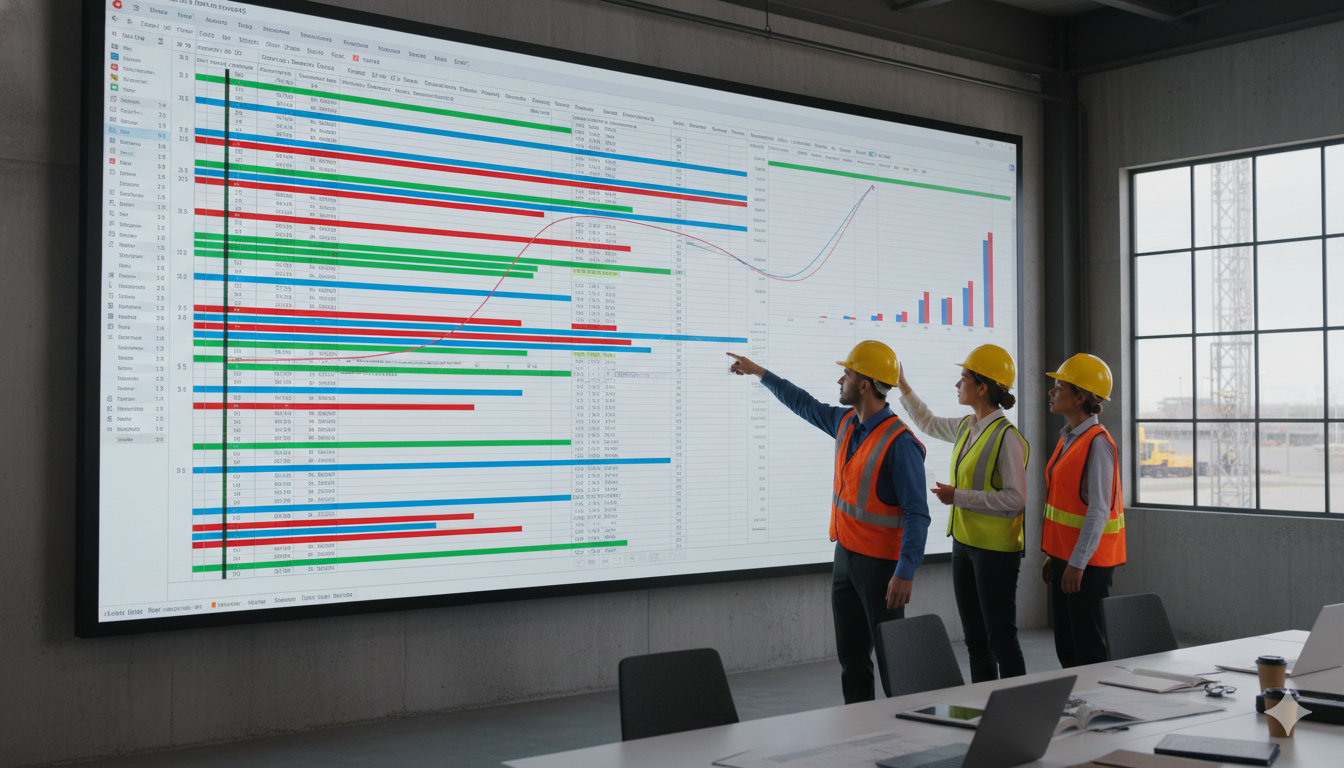

Piping specifications are technical documents created by private companies that outline requirements for materials, components, or services that exceed standard code requirements. These specifications allow buyers to include special conditions based on specific design and service needs, enabling product customization. These requirements must be met. Typically, oil and gas facilities develop their specifications during the Front-End Engineering and Design (FEED) stage or adopt existing specifications from established companies like Shell, Bechtel, EIL, and Chevron.

Why Are Piping Specifications So Important?

The need for these detailed specifications boils down to several critical factors:

- Customization and Special Requirements: They enable buyers to integrate project-specific needs, ensuring the piping system is precisely designed for its intended use, which enhances performance, reliability, and safety.

- Ensuring Compliance and Quality: When requirements are included in the specifications, they become mandatory. This guarantees that all piping components are manufactured and installed according to industry regulations and best practices, maintaining high standards of safety and performance.

- Streamlining Engineering Processes: Clear guidelines reduce the risk of errors, delays, and costly rework during a project, making the entire engineering process more efficient.

- Utilizing Established Standards: Many oil and gas facilities, for example, develop their specifications during the Front-End Engineering Design (FEED) stage or use proven ones from industry leaders like Shell or Chevron. This provides a reliable framework built on extensive expertise.

In essence, piping specifications are fundamental for designing, constructing, and maintaining piping systems that are safe, reliable, and cost-effective.

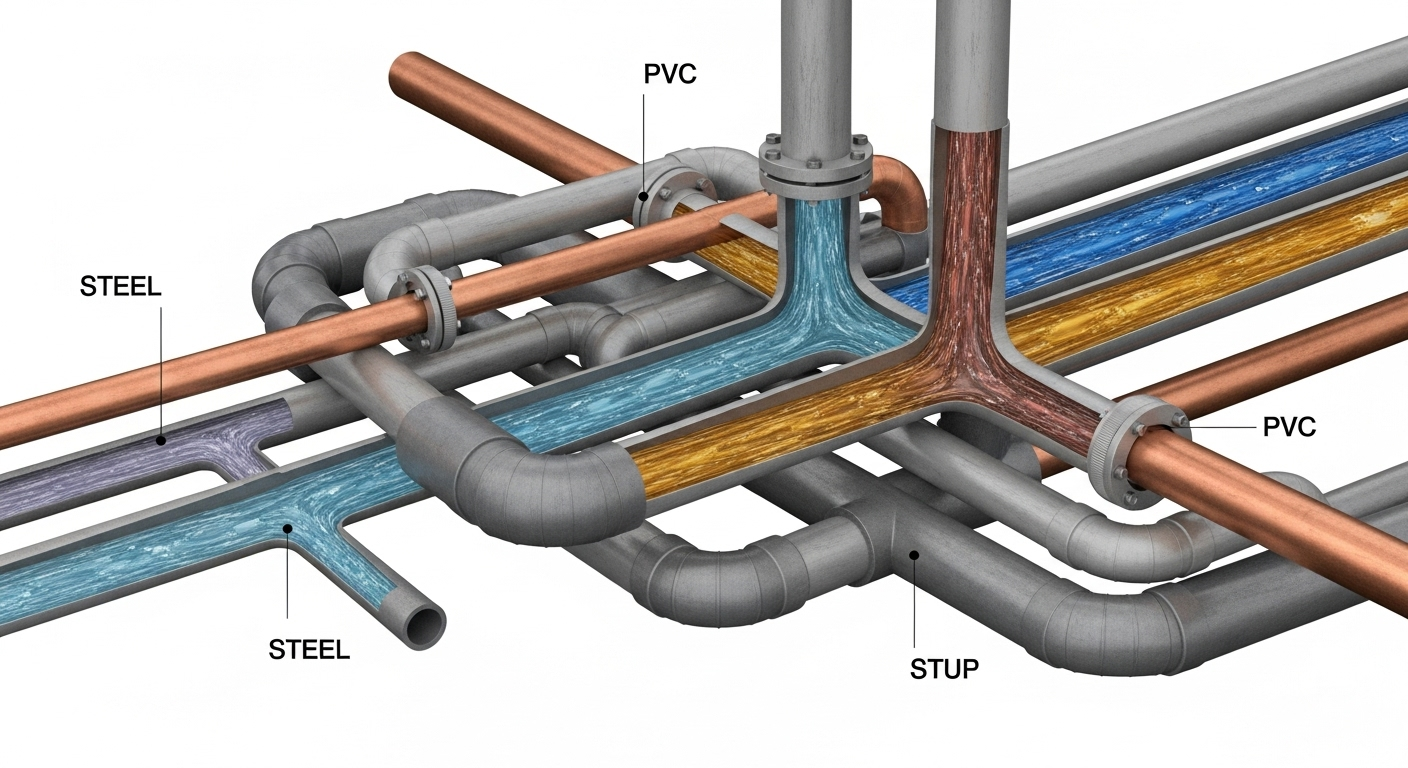

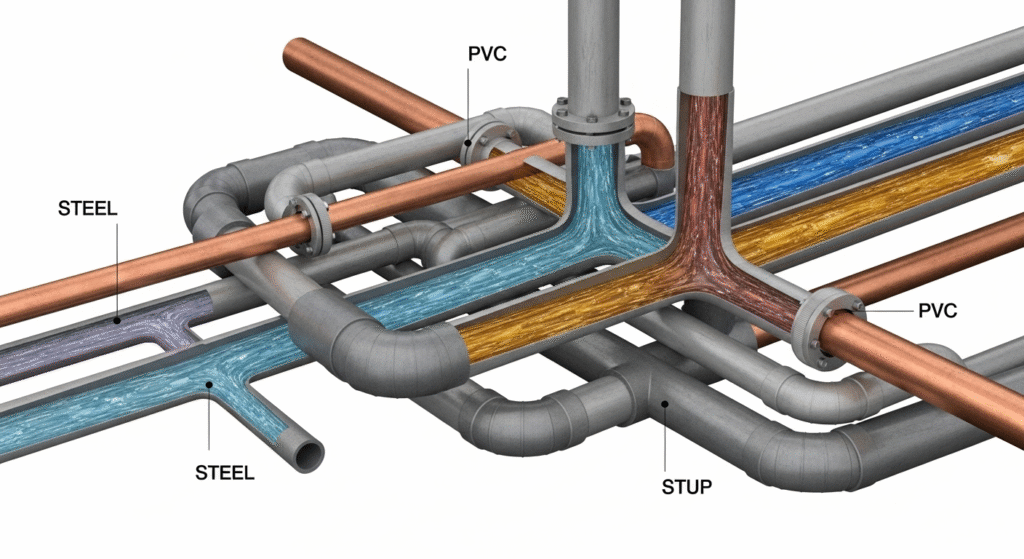

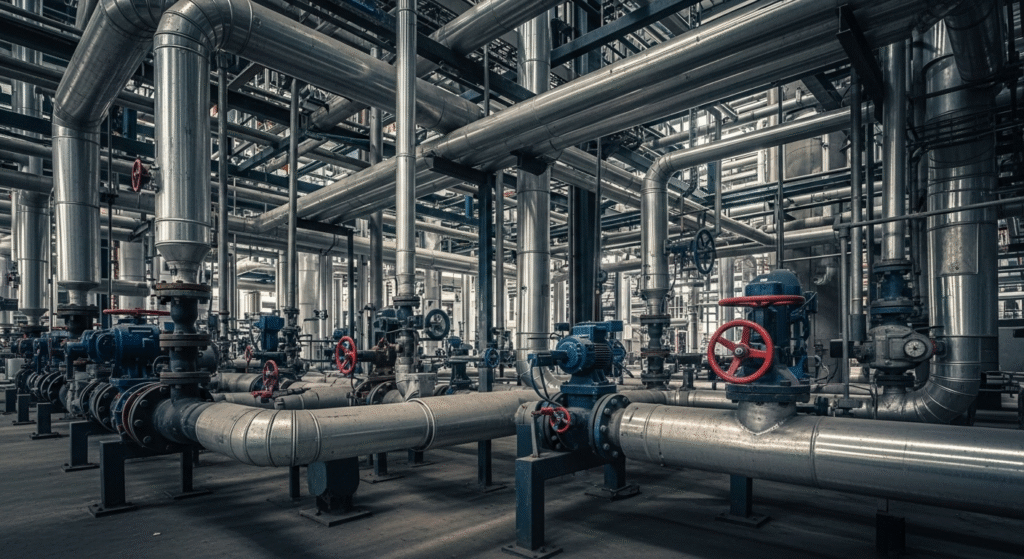

Components of a Piping System

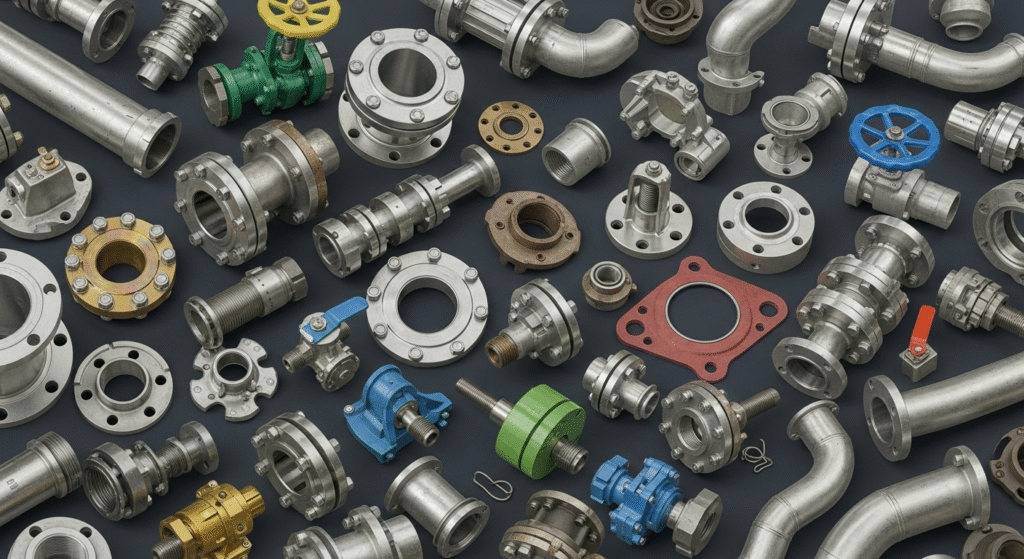

A piping system is far more than just pipes! It’s a complex assembly of various mechanical elements working together to safely and efficiently transport fluids, gases, or even slurries. Here are the main components you’ll find:

- Pipes: These are the fundamental conduits for transporting fluids. The choice of pipe material and size is critical, directly impacting the system’s performance and longevity. Common materials include carbon steel (known for strength and high-pressure/temperature applications), stainless steel (for corrosion resistance), copper (for thermal conductivity and plumbing), and plastics like PVC and HDPE (for chemical resistance and ease of installation).

- Fittings: These are essential for connecting pipes and changing the direction, size, or branching of the piping system. Common types include elbows (to change direction), tees (to split or combine flow), and reducers (to adjust pipe diameter). Proper selection and installation of fittings ensure leak-free connections and efficient flow.

- Valves: Valves are like the traffic cops of a piping system, allowing you to control, isolate, regulate, or direct the flow and pressure of fluids. Examples include gate valves (for on/off control), globe valves (for precise flow regulation), ball valves (for quick shutoff), butterfly valves (compact for throttling), and check valves (to prevent backflow).

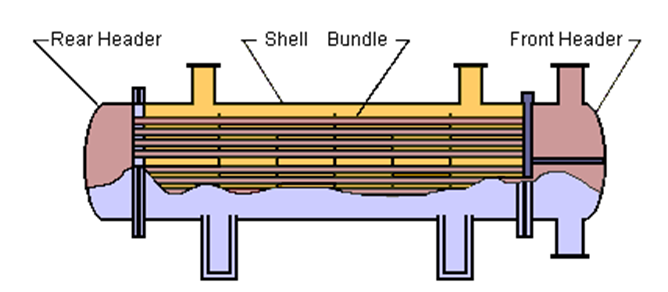

- Flanges and Gaskets: Flanges are used to connect pipes, valves, and other equipment, often allowing for easy assembly or disassembly. Gaskets are placed between flanges to create a tight, leak-proof seal. Common flange types are weld neck (high strength), slip-on (easy installation), and blind (to close off pipe ends).

- Supports and Hangers: These components are vital for maintaining the position of pipes, preventing sagging, and reducing stress on the system. They ensure stability and safety, and help manage movement caused by thermal expansion and contraction. Types include pipe clamps, hangers, guides, and anchors.

- Insulation and Expansion Joints: Insulation materials help maintain temperature control and prevent energy loss. Expansion joints are designed to accommodate thermal expansion and contraction, reducing stress on the pipes.

Defining a Piping System

At its core, a piping system is an assembly where these various components – pipes, fittings, valves, and other specialty parts – are joined together to perform specific functions. These functions include conveying, distributing, mixing, separating, discharging, metering, controlling, or stopping the flow of fluids.

In industrial settings, piping systems act as “circulatory networks,” transporting fluids, gases, and sometimes even solids. They are the backbone that supports operations by ensuring a smooth, safe, and controlled flow of materials, crucial for efficiency, safety, cost-effectiveness, and reliability. These systems are meticulously designed to handle specific pressures, temperatures, and flow rates.