Learn the key difference between long activities and the critical path (zero float) in oil and gas turnaround (TA) management. Discover how critical path planning, resource allocation, and risk control ensure successful and timely plant shutdowns.

Long Activities and the Critical Path in Turnaround (TA) Projects

In the oil and gas industry, turnarounds (TAs)—planned shutdowns for maintenance and inspection—are among the most complex and costly operations. Managing them successfully requires a deep understanding of scheduling, prioritization, and resource control.

Two essential project management concepts in this process are “long activities” and the “critical path” (zero float).

This guide explains these concepts, how they connect, and their impact on turnaround success.

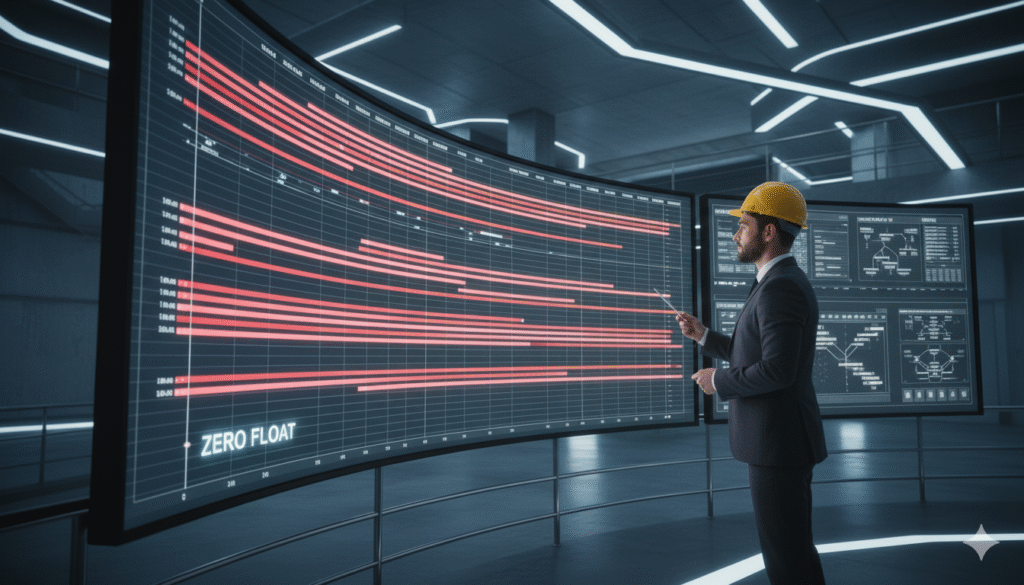

What Is Zero Float in Project Management?

Zero float, also known as zero slack, refers to an activity that has no schedule flexibility.

If such a task is delayed, the entire project completion date is delayed equally.

Key Characteristics of Zero Float Activities

- Critical Importance: They lie on the critical path, the longest sequence of dependent tasks in a project.

- Impact of Delay: Any delay to a zero-float activity delays the overall project completion.

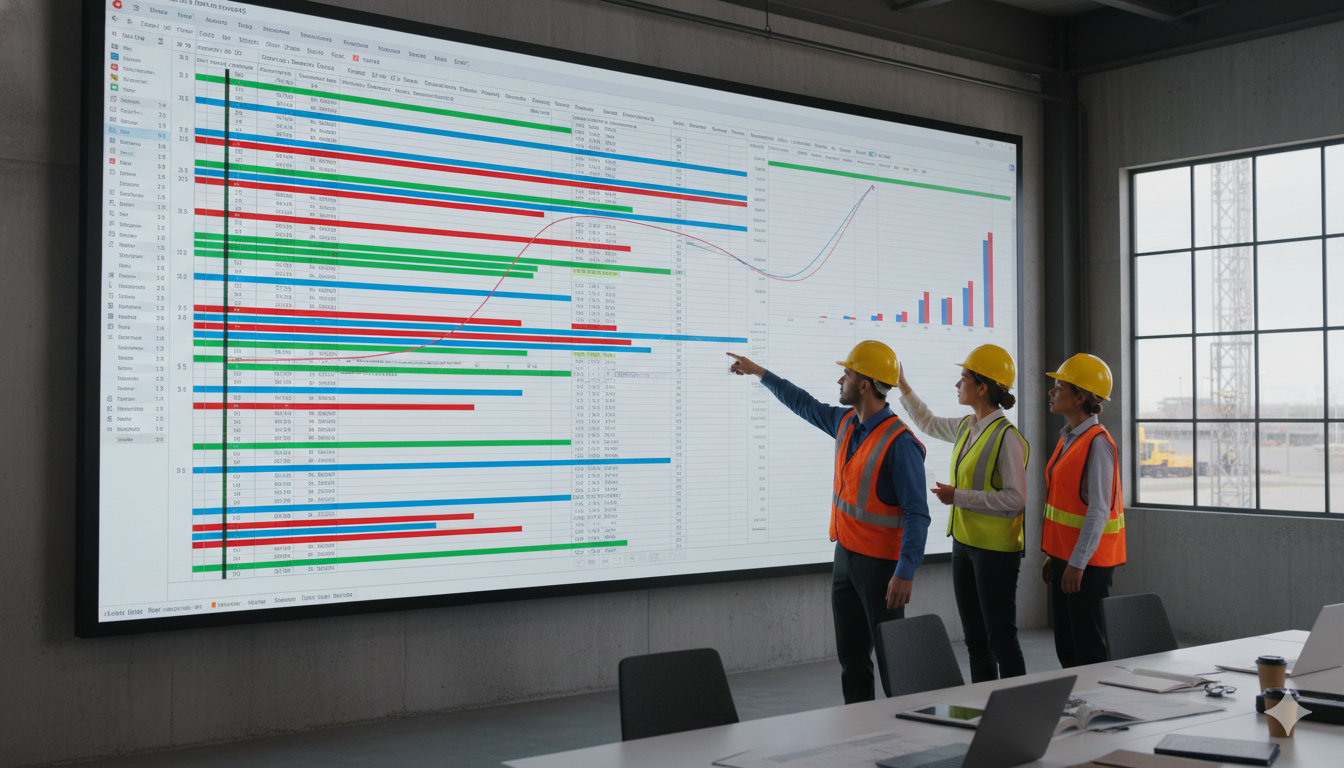

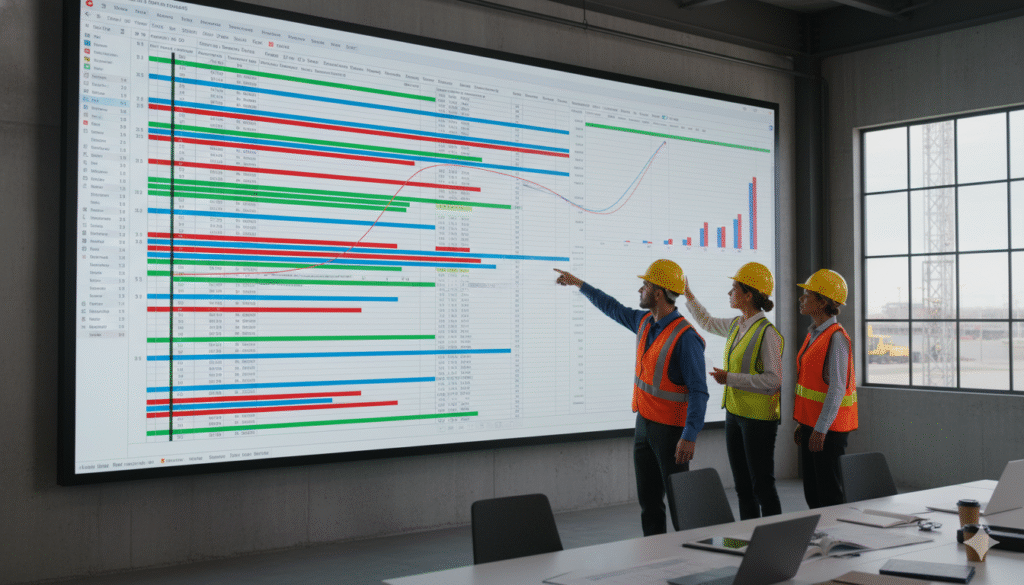

- Monitoring: Project teams track these tasks closely using scheduling tools like Primavera P6.

- Resource Focus: They receive top priority for skilled labor, equipment, and supervision.

Activities with zero float are the backbone of the turnaround timeline—miss them, and the entire project slips.

Understanding Long Activities

While “zero float” is a defined project term, “long activity” is more descriptive.

It refers to tasks that consume significant time relative to other activities in the project.

Common Types of Long Activities

- Extended Duration Tasks: Long-term welding, inspection, or construction work.

- Project-Long Activities: Continuous tasks like monitoring, documentation, or stakeholder communication.

- Process Chains: Sequential operations performed by the same team, often lengthy and labor-intensive.

A long activity may or may not fall on the critical path—it depends on the project’s dependency network and schedule.

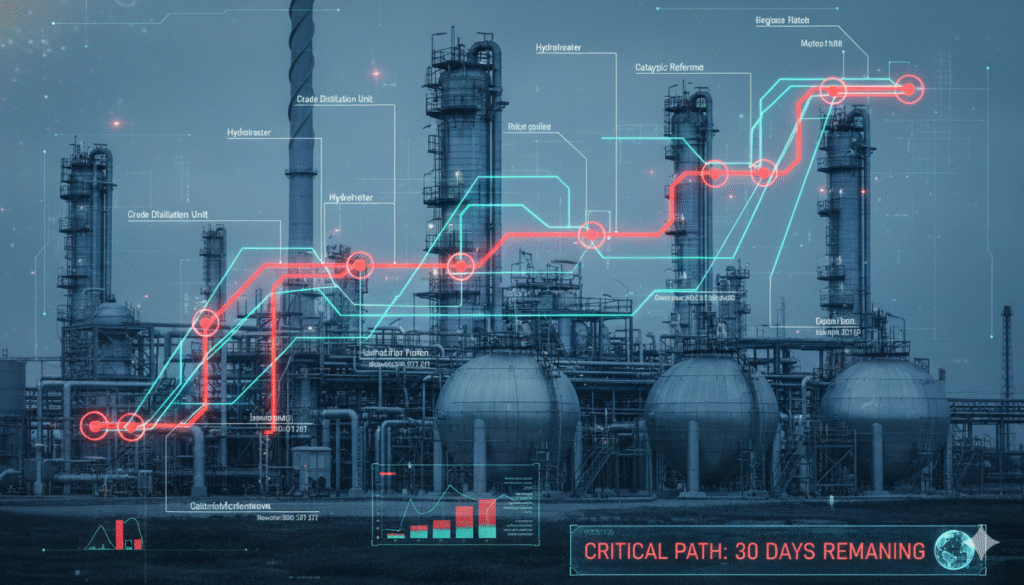

The Critical Path in Turnaround Management

The critical path defines the minimum time required to complete a turnaround.

It’s the longest series of dependent tasks—from shutdown to startup—that determines project completion.

Key Features of the Critical Path

- Modeling and Integration: The schedule includes all activities and durations using CPM tools.

- Tracking and Control: Daily updates ensure visibility of delays or deviations.

- Dynamic Adjustments: The critical path can shift as new work is discovered during execution.

- Optimization: Before freezing the schedule, planners analyze the critical path and reduce duration through sequencing or resource adjustment.

- Performance Metrics: KPIs track hours ahead or behind schedule, using total float as a measure.

In short, controlling the critical path is essential to completing a turnaround efficiently.

Activities That Drive the Critical Path in a Turnaround

Turnaround durations depend largely on the scope and complexity of maintenance work.

Certain activities often become critical due to resource limits, high-risk operations, or complex dependencies.

1. Specialized Skills and Resource Constraints

- Shortage of alloy-coded welders or other certified trades can cause major schedule delays.

- Specialized tools and equipment, like PWHT rigs or high-pressure cleaning systems, must be carefully scheduled.

- Resource leveling ensures optimal distribution of skilled labor and avoids peak overloads.

2. Vessel Internals and Inspection

- Opening and inspecting large pressure vessels introduces uncertainty due to potential discovery of new defects.

- Inspection “hold points” (such as X-ray approvals) may temporarily halt progress until cleared.

- PERT analysis helps estimate uncertain task durations realistically.

3. Preparation and Pre-Turnaround Work

- Pre-fabrication reduces workload during the shutdown phase.

- Pre-shutdown logistics—scaffolding, insulation removal, crane setup—must be completed before the plant stops production.

- Effective preparation shortens the intense execution window.

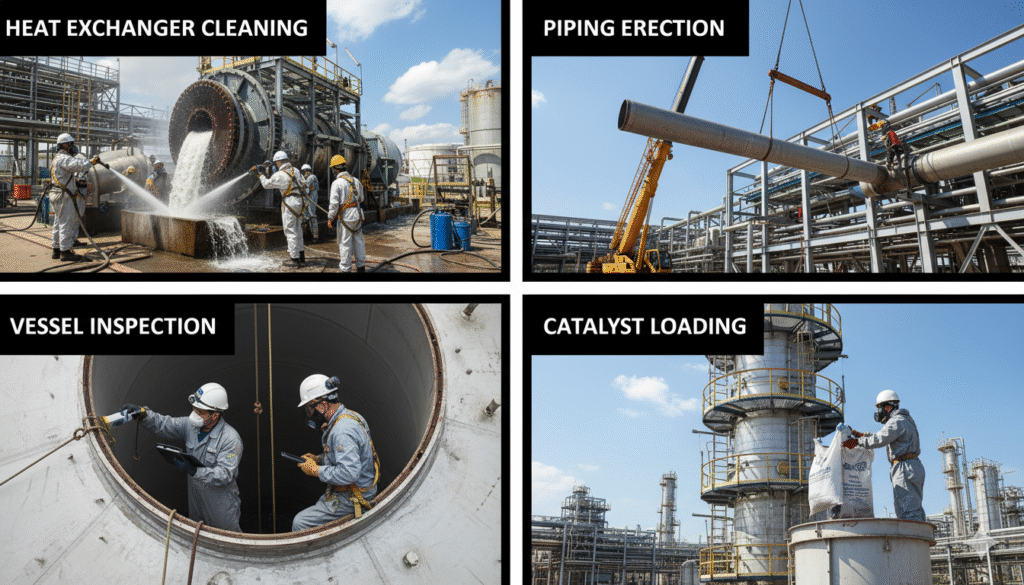

Examples of Long-Duration Activities in Oil and Gas Turnarounds

Several activities in turnaround projects are inherently time-consuming due to scale and complexity:

- Vessel and Column Maintenance: Cleaning, repairing, and inspecting large vessels and reactors.

- Piping Work: Prefabrication, erection, and welding of replacement lines.

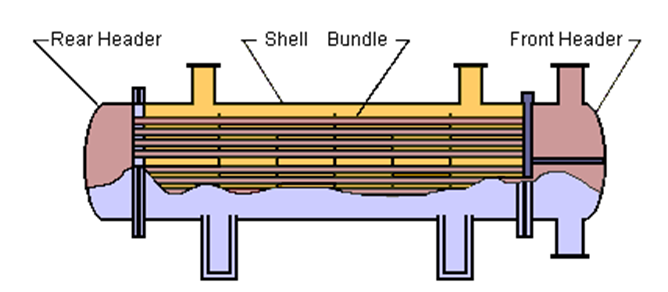

- Heat Exchanger Overhaul: Removing and reinstalling heavy bundles using cranes.

- Major Equipment Overhauls: Disassembling turbines, compressors, and pumps.

- Catalyst Handling: Safe removal and loading of catalyst materials under strict protocols.

- Construction and Modifications: Structural or mechanical upgrades requiring multiple subcontractors.

- Pre-Turnaround Activities: Engineering design and long-lead procurement.

- Startup and Commissioning: Controlled ramp-up of the plant after completion.

Each of these long-duration activities has the potential to drive or extend the critical path.

Managing the Critical Path Effectively

Turnarounds are planned and managed using the Critical Path Method (CPM).

Proper management ensures timely execution, cost control, and safety.

1. Early and Detailed Planning

Defining scope, sequencing tasks, and estimating durations early helps identify the critical path before execution.

2. Resource Prioritization

Critical activities get priority for manpower, tools, and materials to avoid bottlenecks.

3. Real-Time Monitoring

Tools like Primavera P6 provide live tracking of progress, allowing quick response to potential delays.

4. Pre-Inspections

Conducting pre-turnaround inspections prevents surprises during execution, saving valuable time.

5. Risk Mitigation

Planners prepare contingency plans for predictable risks like bad weather, equipment failure, or delayed deliveries.

6. Scope Control

Limiting “scope creep” prevents unplanned work from affecting the critical path schedule.

7. Schedule Compression Techniques

When delays occur:

- Crashing: Add more resources to critical tasks.

- Fast-Tracking: Execute tasks in parallel to save time (with careful risk control).

In turnaround management, understanding the critical path and long activities is vital for success.

The critical path determines when a project will finish, while long activities indicate where most time and effort are spent.

By integrating smart planning, effective resource management, and proactive monitoring through Primavera P6 and CPM techniques, oil and gas companies can achieve shorter, safer, and more cost-effective turnarounds—keeping operations efficient and profitable.

Frequently Asked Questions (FAQ)

1. What is a long activity in turnaround management?

A long activity is a task that takes significantly more time to complete than other activities in the project. In oil and gas turnarounds, examples include vessel inspection, piping fabrication, or equipment overhaul. These activities often influence the overall project duration and may fall on the critical path if not managed properly.

2. What does zero float mean in project scheduling?

Zero float (or zero slack) means that a task has no scheduling flexibility. Any delay in that activity will directly delay the project’s completion. Activities with zero float are part of the critical path, which defines the minimum time needed to complete a turnaround or shutdown.

3. Why is the critical path important in turnaround projects?

The critical path identifies the longest chain of dependent tasks that determines when the turnaround will finish. Managing it ensures that high-priority, time-sensitive tasks stay on schedule, preventing costly delays in restarting plant operations.

4. How can project managers control the critical path in oil and gas turnarounds?

Project managers use tools like Primavera P6 to track progress and adjust schedules. They also use strategies such as crashing (adding extra resources) and fast-tracking (performing tasks in parallel) to recover lost time on critical activities.

5. What are examples of long-duration activities in refinery turnarounds?

Common long-duration activities include:

- Vessel and column maintenance

- Piping replacement and welding

- Heat exchanger cleaning and bundle pulling

- Catalyst loading and unloading

- Major equipment overhauls

These activities often require specialized labor, heavy equipment, and precise coordination.

6. How do pre-turnaround activities affect the critical path?

Pre-turnaround activities such as scaffolding, prefabrication, and material preparation reduce workload during shutdown. Completing these tasks early prevents them from becoming critical-path activities and shortens overall turnaround duration.

7. What software is used to manage turnaround schedules?

The most widely used tools are Primavera P6 and OpenPlan, which apply the Critical Path Method (CPM) to model, track, and optimize all turnaround activities—from planning to execution and commissioning.

8. Can the critical path change during execution?

Yes. The critical path is dynamic and can shift if new issues arise, such as additional repair work or material delays. Continuous schedule monitoring helps identify and adjust to new critical activities in real time.