Plant Turnaround and Shutdown Management in the Oil and Gas Industry: Planning, Phases, and Successful Execution

What is a plant Shutdown / Turnaround? (Oil and Gas)

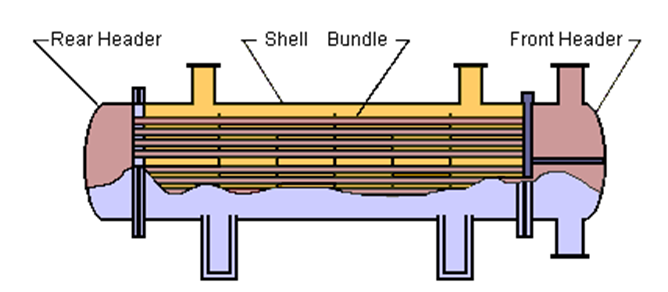

Industrial plants in the oil and gas sector periodically require preventive maintenance, renovations, or upgrades. These essential activities help ensure safe operations, maintain competitiveness, and comply with government regulations. Often, these activities necessitate the partial or complete shutdown of production at refineries, which are known as turnarounds.

Turnarounds are among the most complex and costly events in the oil and gas, petrochemical, and power industries. Successfully executing a turnaround requires meticulous planning, careful scheduling, and effective control during the execution process.

Most oil and gas industries undergo a turnaround every three to five years. Each turnaround requires extensive planning and careful coordination of labor and materials. Typically, the shutdown occurs when production is at its lowest, making skilled labor more readily available. Some turnarounds take just a few weeks to complete, while others may extend over several months. The duration of a turnaround depends on the project’s scope and any issues that may arise during the process. Additionally, most refineries conduct thorough inspections and testing during a turnaround. If any problems are identified during these inspections or tests, the turnaround may be extended.

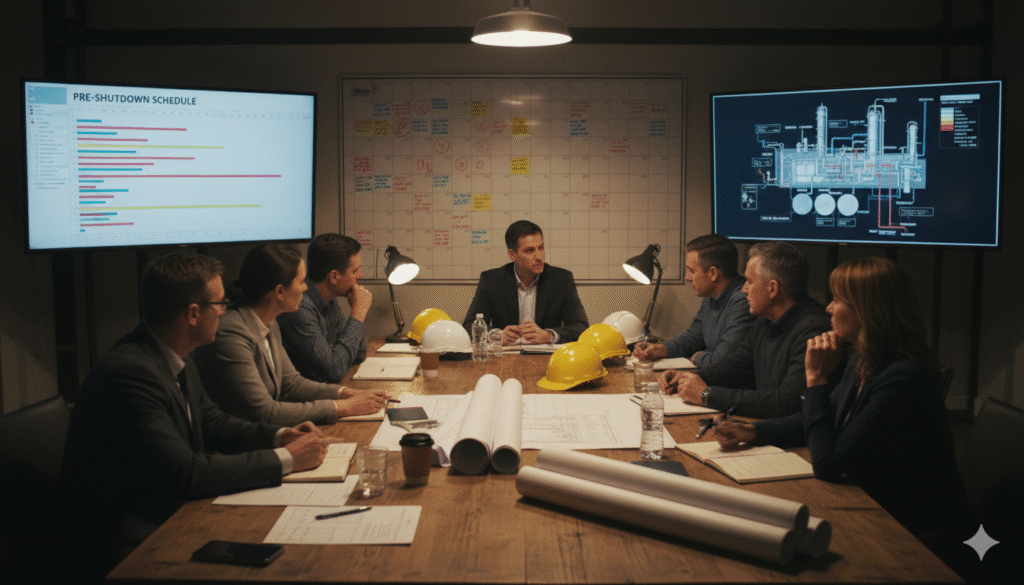

Key Factors for a Successful Shutdown/Turnaround!

1. Meticulous Planning – Every task should be planned in detail several months in advance.

2. Safety First – Given the large number of contractors involved and the many activities taking place simultaneously, safety is essential and must be prioritized.

3. Discipline in Execution – Sticking to the schedule, effectively coordinating contractors, and maintaining quality control are crucial for success.

4. Cost and Time Optimization – Saving time translates into significant financial savings, so every hour counts.

5. Continuous Learning and Improvement – Each turnaround should set a standard for future projects, promoting ongoing development.

What is an Oil and Gas Industrial Shutdown? What are the Pre-Shutdown Activities?

Pre-Shutdown!

The pre-shutdown phase is the initial stage of the shutdown process, focusing on planning and scheduling for the upcoming disruption in operations.

Pre-Shutdown Activities!

1. Define the overall scope of work and the specific tasks involved. Prepare detailed method statements for each job, along with a Job Safety Analysis (JSA). All relevant training related to jobs, including H2S awareness, confined space safety, and work at height, fire watch, and hole watch, etc.

2. Conduct site inspections to evaluate blind positions, review entry points, Tagging for valve replacement and the removal of the valve for repairs, assess scaffolding as per the scope of work, arrange crane setups, inspect insulation removal areas, and check the condition of fasteners.

3. Obtain approval for any temporary laydown areas. Schedule welder qualification tests based on the specific job requirements. Prepare work permits according to the specific job requirements.

4. Initiate procurement processes for necessary spare parts, such as fasteners and gaskets, ventilation equipment, ensuring that all items are available before the shutdown begins.

5. Ensure the availability of tested hoses for draining, purging, and steaming operations.

6. Verify that all lifting tools and equipment are certified and color-coded.

7. Remove insulation as necessary in designated areas.

8. Transfer all required tools to the designated site tools container.

9. Arrange for all necessary personal protective equipment (PPE) and consumables.

10. Ensure that a sufficient number of pressure gauges are available, covering an appropriate range.

11. Confirm the supply of self-contained breathing apparatus (SCBA) and other respiratory devices for conducting blinding operations.

12. Assist in connecting purging hoses and closing valves.

Feel free to add more activities as needed based on the specific scope of work requirements.

What Are Plant (Oil & Gas) Shutdown Activities?

Shutdown Overview!

The execution phase of a shutdown project typically lasts between 30 to 45 days. During this time, all processes are halted on the designated start date, also known as the zero date. Equipment is thoroughly cleaned, and access points (manholes) are opened. Preliminary inspections are conducted for both internal and external infrastructure, and any necessary modifications are made based on these inspections.

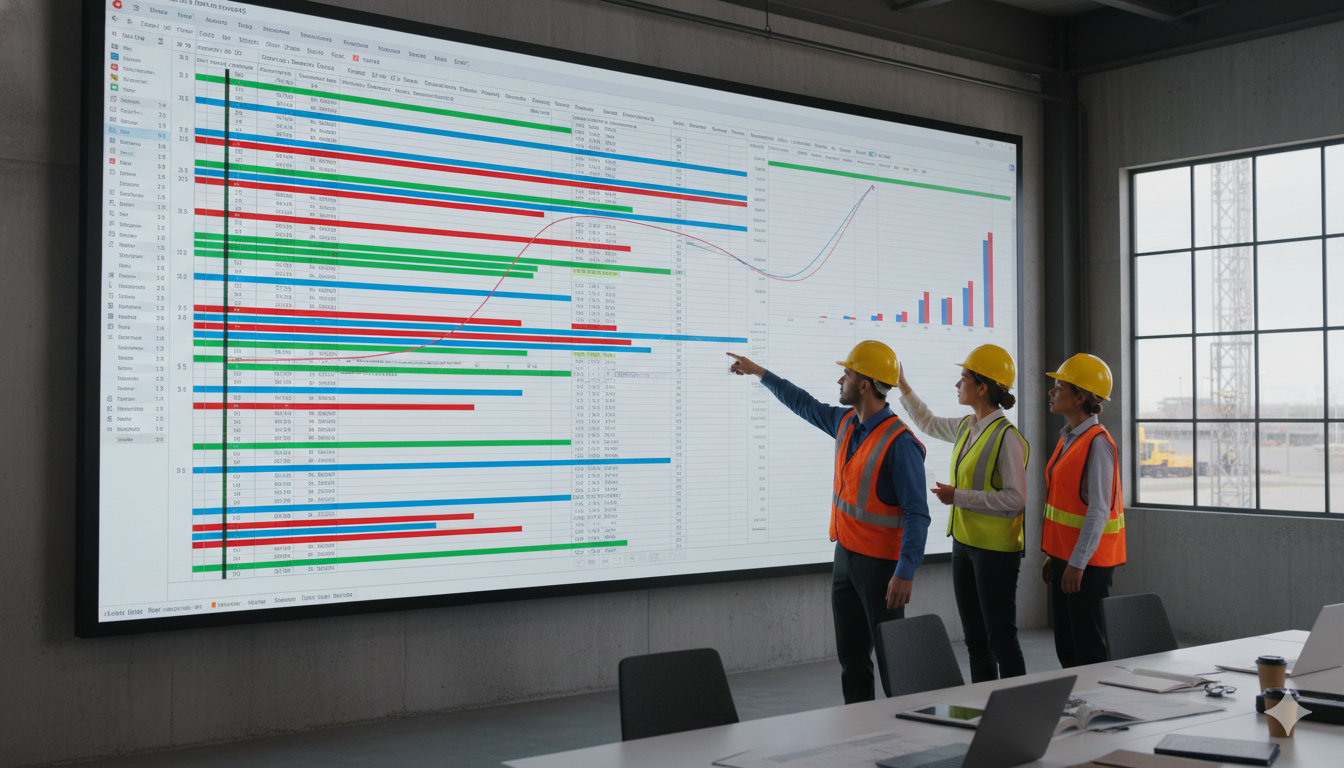

The facility maintenance supervisory staff oversees the execution of the shutdown. We utilize shutdown planner job packs together with a shutdown scheduler to ensure that tasks are completed within the specified timeframe.

Shutdown Activities!

1. Toolbox Talk: A discussion is led by the supervisor, area in-charges, and safety officer covering work ranges, risks, and control measures. Work priorities are assigned according to the schedule. Managing critical path activities requires careful planning and monitoring to avoid delays, as they have zero float and dictate the earliest completion date.

2. Preparation for Work:

– Obtain necessary permits.

– Tag equipment for entry.

– Set up fire watch and hole watch.

– Neutralize and decontaminate equipment.

3. Equipment Setup:

– Install blinds and open manways.

– Set up air movers for ventilation and obtain a gas test certificate.

– Allow equipment to cool down.

4. Confined Space Scheduling:

– Create a schedule for activities in confined spaces.

– Track entry and exit times.

– Install temporary lighting.

5. Protection Measures: Protect all bottom nozzles with metal boxes to prevent the entry of foreign materials.

6. Quality Control: Provide the Quality Control (QC) team with preliminary examination reports and seek their advice.

7. Scaffolding: Erect internal scaffolding as needed.

8. Completion of Activities: Based on QC recommendations and the scope of work, complete all required activities, including:

– Cleaning (mechanical cleaning, high-pressure water jetting)

– Testing (hydrostatic testing, X-ray, etc.)

9. Final Inspection: Schedule a final inspection and coordinate the removal of internal scaffolding.

10. Certification: Obtain a box-up certificate from QC, process, maintenance, and operations.

11. Torquing: Ensure that QC and maintenance personnel witness the torquing process.

12. Cleanup: Conduct general cleanup and housekeeping.

Feel free to add any additional activities as required by the scope of work.

Plant (Oil & Gas) Shutdown / Post-Shutdown Overview!

Post-Shutdown Activities!

Once the shutdown tasks are completed, it is essential to remove all testing and supporting equipment from the site. The management methods used throughout the shutdown process should be thoroughly documented to facilitate planning for future shutdowns.

Key Post-Shutdown Activities!

1. Assist with startup operations.

2. Disconnect all hoses, repair insulation, and remove any external scaffolding.

3. Transition tools, supplies, and temporary laydown bins to their designated permanent locations.

4. Upon successful commissioning, obtain the Final Acceptance Certificate (FAC) from the Quality Control, Planning, Operations, and Maintenance teams, and submit the close-out report.

Turnaround Final Report!

At the end of every turnaround, it is crucial to prepare a final report for historical reference and to justify the results in terms of time and cost to management. Keep one copy for the Planning file and distribute additional copies to upper management as necessary.

In the oil refining and petrochemical processing industries, specific terminology is used for maintenance projects. In this context, “turnaround” refers to all types of industrial projects for existing process plants. This includes inspections, testing, shutdowns, emergency outages, debottlenecking projects, revamps, catalyst regeneration, and more. These projects require shutting down the operating plant until the work is completed, after which the plant is restarted—hence the term “turning around” the unit or plant.

Effective planning and scheduling of turnaround projects are critical functions that significantly influence maintenance costs and the overall profitability of a process plant. Maintenance costs arise from the use of manpower, equipment, and materials.

To control costs, it is essential to ensure the efficient use of manpower and equipment. Through careful planning and scheduling, a maintenance planner or scheduler can help the organization reduce manpower costs, minimize downtime, and achieve optimal equipment utilization.

The key to developing an efficient plan lies in eliminating wasted movement, unnecessary actions or transports, and minimizing the redeployment of crew and equipment.